First, Matt, Mayhem’ Biolos, you shape the Lost Boards. Can you explain for us what the differences are between Lib, Lost and Mayhem?

Matt: Yeah, sure! LIB is short for Lib Tech. First of all a snowboard brand, who specialised in technical, sustainable manufacturing with a focus on innovation and performance without sacrificing ecologically minded practices. And of course for while also doing amazing surfboards …Lost is a brand. We specialise in poking fun at stupid questions, not giving two fucks or taking interviews too seriously☺. We’ve been around a while and are known for our sarcastic clothing, sardonic videos, sarcastic demeanour and halo go sac-religious surfboards for the Pros and the Bros.

It’s nearly 40 years ago that you started shaping surfboards. Can you give us a brief summary of how you got into shaping, what you got interested in and how you came to working with Lib Tech?

Matt: Actually I started shaping boards in 1987, so it’s 35 years now to be exact.

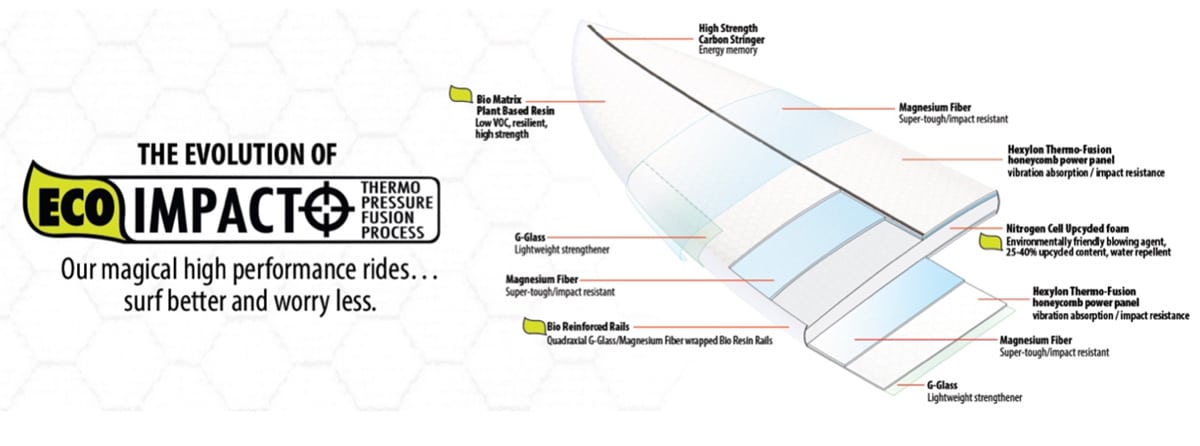

I’ve always respected LIBs common values of not taking marketing and image side of things too seriously, backed up with a commitment to performance, progression and building most of their products themselves. I believe there is a growing demand for a stronger, “greener” more sustainable built surfboard. I believed that it was time leaving the artificially marketed “sustainable“ boards that I was previously working with behind. Some are simply hiding mass produced low labor imported product behind deceiving marketing and so I made the move to work with LIB. Strong, light, long lasting, easily replicated, cleanly built boards, ecologically minded with respect for the earth, worker that builds them and the surfer who rides them.

Pete, you co-founded Mervin Manufacturing in 1977 with Mike Olson. The company is the longest running snowboard manufacturer in the USA. When did the process start designing and producing Lib Tech surfboards?

Pete: We grew up isolated from surf culture in the northern corner of the USA where there were almost no surfers or surf shops so we always made our own surfboards and grew to love the craft and process. Wetsuits were not great back then so snowboarded all winter and built surfboards for the spring, summer and fall when there was more light and it was a bit warmer. In the beginning Mike Olsen built surfboards and sailboards to help fund the snowboard projects. We were constantly building boards with an alternative materials mindset but the process of designing the environmentally nicer, dang difficult to ding Lib Tech construction as it is now started in the early 2000’s. We had always felt that traditional polyester construction surfboards were very toxic to make and way too fragile. We felt like there had to be a better way to build surfboards so in about 2003 Mike started to dedicate a significant portion of his time to developing alternative surf constructions.

How did the connection between Lib and Lost start?

Pete: Mike and I had always loved Matt and Lost’s punk rock surf attitude combined with high performance shapes and surfing. We watched all the 90s dysfunctional videos and soaked up the fun…it felt in a lot of ways like Lost was a sister company to Lib Tech. We both came up in board sports around the same time and pushed board building and performance…us in snow and Matt in Surf. Matt is a snowboarder and he had reached out to us to work on some snowboards over the years and when we thought of a shaper we would like to work with in surf he was at the top of our list. One of the things we really liked about Matt and Lost was his ability to build high performance boards for the world’s best but also clearly understand and adapt that technology to create shapes that suit the needs of a more average recreational surfer. Shapes like the Puddle Jumper, Rocket Redux, HYDRA and the all new RNF 96’ really fit the Lib Tech customer and construction well.

Lib Tech surfboards stand out in terms of the design and the used materials. How did the process look like inventing the Lib x Lost boards?

Matt: I was not part of the process. But I have been thoroughly blown away, when busting the factory and witnessing the extremely unique system they have created and continue to repeated refine.

Pete: We had always been frustrated with how toxic building surfboards is and how delicate the boards are. We love surfing and had always wanted to get involved in the industry in some way for fun and to have an off season business along to balance our snowboard building. We didn’t want to get involved in surf unless we had something to offer. So when we committed to surf Mike set out to completely reinvent surfboard construction in a more environmentally friendly way for the board builder and the planet. We wanted a stronger high performance surfboard. We wanted to build the boards here in the USA at our Mervin facility so we could control all the variables from design, supply chain to process. It was a huge task and took about 10 years to develop the process through lots of experiments, trials and errors. The process and materials we are using is radically different than anything else being done out there. Mike always says every board is a miracle and that it shouldn’t work but it does!

As a co-founder and creative person, what are you involved in the company today in general & especially when it comes to surfing?

Pete: Both Mike and I love board building, creativity and problem solving and are actively involved in manufacturing and all aspects of Mervin. My current title is VP of marketing and I work with our engineering, design and marketing teams on all our boards and branding for surf and snow. I love surfing so I have been putting quite a bit of energy into helping on that front. I run our surf social media, work with Matt on planning and executing all our Lib x Lost snowboards and surfboards, work with our surfers and crew to coordinate all surf marketing. Work with Hendo and Olson on the construction, process and internal surf strategies. We live at the beach so I get in water as much as possible. I am passionate surf fan and nerd for all things and eras of surf design especially the future. I ride everything we make and always love exploring any interesting shapes out there and trying to understand what the shaper had in mind. Our surf program has been a real joy to be involved with…it feels like one of Mikes and my childhood dreams came true.

Matt you shape boards for many professional surfers like Kolohe Andino and Carissa Moore. Do they come up with an idea for a new shapes, or do you suggest what’s next?

Matt: For LIB Tech, most of the models we put into production are more my ideas based off the needs of the detest surfer. These designs trialed are tested by our team of athletes in the development stage before we invest in translating into LIB contribution. Many of our Top pros use the LIB boards often. That said, we have released a “KOLOHE ANDINO SWORD-FISH” model, based exactly off Kolohes magic small wave fish. It’s a fun collab that he really rips on.

This year, we released a Mason Ho / LIB collab, as well. His new performance shortboard, the “LITTLE WING”. A full size scale is available.

During the pandemic, there was a shortage of materials, especially foam. Did you have troubles with it? And do you think surfboard prices will increase due to that?

Matt: We had no shortage of materials whatsoever. But the cost of raw materials has been on a steady rise. Labor costs are also (understandably) on the rise and training / attracting the skilled labor needed requires more investment than before. Costs go up / Prices go up. Been like that forever.

Pete: We have many unique materials in our EcoImpacto environmentally nicer construction and many of them have been a bit more challenging to get when we need them. Mike is our materials expert and he works with the supply chain team to make sure we have what we need when we need it. We really focused on placing larger materials orders early to deal with longer lead times and uncertainty…so far so good…it’s something we keep our eye on every day. We are seeing prices of almost everything from cars, groceries to sporting increase because of the pandemic and general inflation. The goal is to find a balance and keep the boards affordable and competitive in the market.

What were the major steps so far within the Lib X Lost Collab, where are you today and what do you think will the future bring?

Matt: The steps have been working hard to gain acceptance in an often closed circle, closed minded market. It takes time for people to appreciate things like the eco minded materials and manufacturing process, as well as understanding that these boards are made in USA. Not in some third world, low labor cost factory. They are the worlds strongest, most sustainably built production surfboards, featuring the cleanest and safest materials available, anywhere in the world. The weight and flex are now right on par with a classic built PU/PE surfboard. We have been aggressive in developing models and sizes that fit most everyone.

Pete: Matt is always fun for us to work with he is a highly motivated, creative, competitive person and a perfectionist when it comes to all aspects of design. He pushes us to be better on both the surf and snow front. It sometimes is a pain in the ass ha!…but, it always is a blessing. We completely redesigned all three of Matt’s snowboard models for this upcoming year and they are riding insane.

During the pandemic, there was a shortage of materials, especially foam. Did you have troubles with it? And do you think surfboard prices will increase due to that?

Matt: We had no shortage of materials whatsoever. But the cost of raw materials has been on a steady rise. Labor costs are also (understandably) on the rise and training / attracting the skilled labor needed requires more investment than before. Costs go up / Prices go up. Been like that forever.

Pete: We have many unique materials in our EcoImpacto environmentally nicer construction and many of them have been a bit more challenging to get when we need them. Mike is our materials expert and he works with the supply chain team to make sure we have what we need when we need it. We really focused on placing larger materials orders early to deal with longer lead times and uncertainty…so far so good…it’s something we keep our eye on every day. We are seeing prices of almost everything from cars, groceries to sporting increase because of the pandemic and general inflation. The goal is to find a balance and keep the boards affordable and competitive in the market.

What were the major steps so far within the Lib X Lost Collab, where are you today and what do you think will the future bring?

Matt: The steps have been working hard to gain acceptance in an often closed circle, closed minded market. It takes time for people to appreciate things like the eco minded materials and manufacturing process, as well as understanding that these boards are made in USA. Not in some third world, low labor cost factory. They are the worlds strongest, most sustainably built production surfboards, featuring the cleanest and safest materials available, anywhere in the world. The weight and flex are now right on par with a classic built PU/PE surfboard. We have been aggressive in developing models and sizes that fit most everyone.

Pete: Matt is always fun for us to work with he is a highly motivated, creative, competitive person and a perfectionist when it comes to all aspects of design. He pushes us to be better on both the surf and snow front. It sometimes is a pain in the ass ha!…but, it always is a blessing. We completely redesigned all three of Matt’s snowboard models for this upcoming year and they are riding insane. We slowed down the new surf model releases for 2021 because we were overwhelmed by the demand for our existing surf shapes, but we have four really exciting new shapes that came out this spring 22 including some more performance minded shapes.

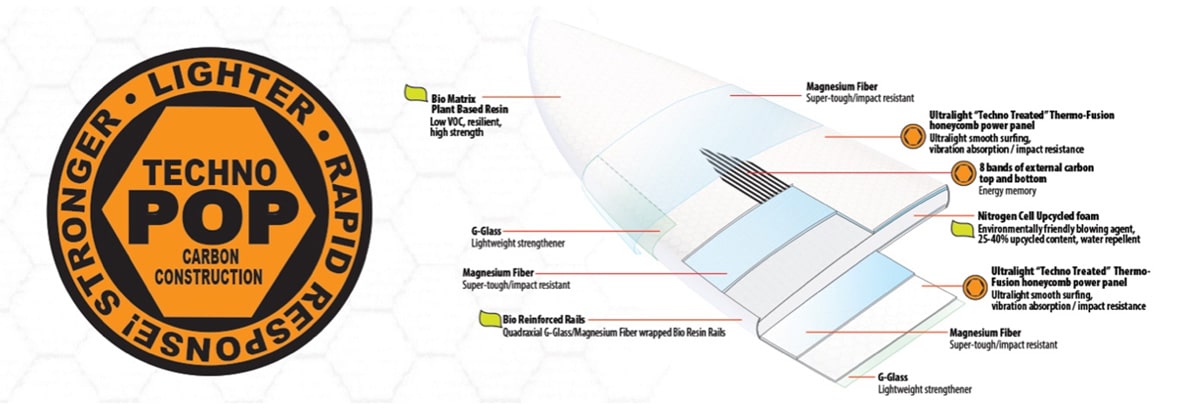

Internally we are constantly improving our surf construction to be lighter, stronger and improve the little details both cosmetically and performance wise. Our latest addition is our Techno Pop construction introduced on Mason Ho’s high performance thumb tail short board – the “Little Wing”

We have a great crew of surfers on the boards giving us feedback and having fun getting content…Matts team in San Clemente, Skin Dog and crew in Santa Cruz, our local shredders and some of the core crew from Tofino BC. We are going to keep working as hard as we can to use our magical Mervin MFG toy factory to do good things for our friends and the planet. Stay tuned for more to come!

Thanks! Pete & Matt